中国水稻科学 ›› 2022, Vol. 36 ›› Issue (4): 377-387.DOI: 10.16819/j.1001-7216.2022.210413

沈泓1,#, 姚栋萍1,2,#, 吴俊1, 罗秋红2, 吴志鹏3, 雷东阳2, 邓启云1, 柏斌1,*( )

)

收稿日期:2021-04-22

修回日期:2021-08-24

出版日期:2022-07-10

发布日期:2022-07-12

通讯作者:

柏斌

作者简介:第一联系人:#共同第一作者

基金资助:

SHEN Hong1,#, YAO Dongping1,2,#, WU Jun1, LUO Qiuhong2, WU Zhipeng3, LEI Dongyang2, DENG Qiyun1, BAI Bin1,*( )

)

Received:2021-04-22

Revised:2021-08-24

Online:2022-07-10

Published:2022-07-12

Contact:

BAI Bin

About author:First author contact:# These authors contributed equally to this work

摘要:

【目的】研究灌浆期不同时段高温对稻米淀粉组成、结构和理化特性的影响,揭示高温对稻米淀粉理化特性影响的时段效应,阐明高温、结构和功能之间的关系。【方法】以耐热水稻品种黄华占和热敏感的9311近等位基因系为实验材料,利用人工气候箱设置高温[38℃(昼)/30℃(夜)]和对照[28℃(昼)/22℃(夜)],研究灌浆前期(齐穗期后1-15 d)和后期(齐穗期后16 d至成熟)高温对稻米的加工品质、外观品质、淀粉组成、支链淀粉链长分布、粒度分布、胶稠度、黏度特性、糊化特性、结晶特性和颗粒形态的影响。【结果】灌浆期高温使糙米率、精米率、整精米率显著下降,使垩白粒率和垩白度显著升高,导致加工品质和外观品质变差。灌浆期高温使总淀粉含量、直链淀粉含量、短支链淀粉含量、大淀粉粒占比、直/支链淀粉比显著下降,而中等支链淀粉含量、小中淀粉粒占比、糊化温度和糊化焓显著上升,黏度特性显著改变,结晶类型不变但结晶度显著改变,淀粉颗粒表面出现小孔,表面变得凹凸不平,导致淀粉颗粒更加碎片化和蒸煮食味品质变劣。灌浆期不同时段高温对稻米品质的影响不同,灌浆前期高温对稻米淀粉的影响大于灌浆后期,耐热品种受影响小于热敏感品种。灌浆前期高温处理下供试材料具有较高的消减值和较低的崩解值,黏度特性变差;灌浆后期高温处理下供试材料具有较低的消减值和较高的崩解值,黏度特性变好。【结论】灌浆前期高温对淀粉理化特性的影响最大,进而导致稻米的加工品质、外观品质和蒸煮食味品质变劣,灌浆后期高温提升了黏度特性。

沈泓, 姚栋萍, 吴俊, 罗秋红, 吴志鹏, 雷东阳, 邓启云, 柏斌. 灌浆期不同时段高温对稻米淀粉理化特性的影响[J]. 中国水稻科学, 2022, 36(4): 377-387.

SHEN Hong, YAO Dongping, WU Jun, LUO Qiuhong, WU Zhipeng, LEI Dongyang, DENG Qiyun, BAI Bin. Effects of High Temperature in Various Phases of Grain Filling on Rice Starch Physicochemical Properties[J]. Chinese Journal OF Rice Science, 2022, 36(4): 377-387.

| 品种 Variety | 处理时段 Treatment period | 糙米率 Brown rice rate/% | 精米率 Milled rice rate/% | 整精米率 Head milled rice rate/% | 长宽比 Length-to-width ratio | 垩白度 Chalkiness/% | 垩白粒率 Chalky grain rate/% |

|---|---|---|---|---|---|---|---|

| 黄华占Huanghuazhan | CT | 83.49±0.35 a | 75.28±0.30 a | 64.44±1.65 a | 3.42±0.03 a | 0.80±0.32 c | 3.67±0.58 c |

| QD | 78.61±0.71 b | 70.06±0.17 b | 29.74±0.51 c | 3.19±0.17 a | 67.47±0.80 a | 93.33±3.51 a | |

| HD | 83.47±1.03 a | 75.25±1.25 a | 46.65±5.84 b | 3.37±0.03 a | 13.06±3.17 b | 24.20±9.73 b | |

| 9311近等基因系9311N | CT | 80.70±0.56 a | 71.84±1.30 a | 68.89±0.76 a | 2.81±0.05 a | 0.62±0.11 c | 3.33±1.53 c |

| QD | 74.12±0.90 b | 65.83±0.64 b | 25.26±0.83 c | 2.67±0.07 b | 75.36±2.19 a | 98.33±1.53 a | |

| HD | 80.53±0.60 a | 70.63±0.54 a | 56.21±1.64 b | 2.75±0.05 ab | 14.52±0.53 b | 28.00±2.00 b |

表1 灌浆期不同时段高温对稻米加工品质和外观品质的影响

Table 1. Effects of high temperature at different times during grain filling on processing quality and appearance quality.

| 品种 Variety | 处理时段 Treatment period | 糙米率 Brown rice rate/% | 精米率 Milled rice rate/% | 整精米率 Head milled rice rate/% | 长宽比 Length-to-width ratio | 垩白度 Chalkiness/% | 垩白粒率 Chalky grain rate/% |

|---|---|---|---|---|---|---|---|

| 黄华占Huanghuazhan | CT | 83.49±0.35 a | 75.28±0.30 a | 64.44±1.65 a | 3.42±0.03 a | 0.80±0.32 c | 3.67±0.58 c |

| QD | 78.61±0.71 b | 70.06±0.17 b | 29.74±0.51 c | 3.19±0.17 a | 67.47±0.80 a | 93.33±3.51 a | |

| HD | 83.47±1.03 a | 75.25±1.25 a | 46.65±5.84 b | 3.37±0.03 a | 13.06±3.17 b | 24.20±9.73 b | |

| 9311近等基因系9311N | CT | 80.70±0.56 a | 71.84±1.30 a | 68.89±0.76 a | 2.81±0.05 a | 0.62±0.11 c | 3.33±1.53 c |

| QD | 74.12±0.90 b | 65.83±0.64 b | 25.26±0.83 c | 2.67±0.07 b | 75.36±2.19 a | 98.33±1.53 a | |

| HD | 80.53±0.60 a | 70.63±0.54 a | 56.21±1.64 b | 2.75±0.05 ab | 14.52±0.53 b | 28.00±2.00 b |

| 品种 Variety | 处理时段 Treatment period | 总淀粉含量 Total starch contents/% | 直链淀粉含量 Amylose content/% | 支链淀粉含量 Amylopectin content/% | 直/支链淀粉比 Amylose/Amylopectin ratio | 胶稠度 Gel consistency /mm |

|---|---|---|---|---|---|---|

| 黄华占Huanghuazhan | CT | 75.12±1.86 a | 17.03±0.25 a | 58.09±2.00 a | 0.29±0.01 a | 62.25±5.32 a |

| QD | 70.55±0.31 b | 12.73±0.10 c | 57.82±0.37 a | 0.22±0 c | 52.50±3.51 b | |

| HD | 75.44±3.95 a | 15.63±0.57 b | 59.82±3.64 a | 0.26±0.01 b | 53.25±2.63 b | |

| 9311近等基因系9311N | CT | 75.57±0.56 a | 12.15±0.37 a | 63.42±0.51 b | 0.19±0.01 a | 70.75±1.71 a |

| QD | 72.15±0.86 b | 7.60±0.26 b | 64.55±1.10 a | 0.12±0 b | 60.75±1.71 b | |

| HD | 71.73±0.37 b | 11.88±0.67 a | 59.85±0.73 c | 0.20±0.01 a | 60.00±2.16 b |

表2 灌浆期不同时段高温对淀粉组分和胶稠度的影响

Table 2. Effects of high temperature at different phases of grain filling on starch composition and gel consistency.

| 品种 Variety | 处理时段 Treatment period | 总淀粉含量 Total starch contents/% | 直链淀粉含量 Amylose content/% | 支链淀粉含量 Amylopectin content/% | 直/支链淀粉比 Amylose/Amylopectin ratio | 胶稠度 Gel consistency /mm |

|---|---|---|---|---|---|---|

| 黄华占Huanghuazhan | CT | 75.12±1.86 a | 17.03±0.25 a | 58.09±2.00 a | 0.29±0.01 a | 62.25±5.32 a |

| QD | 70.55±0.31 b | 12.73±0.10 c | 57.82±0.37 a | 0.22±0 c | 52.50±3.51 b | |

| HD | 75.44±3.95 a | 15.63±0.57 b | 59.82±3.64 a | 0.26±0.01 b | 53.25±2.63 b | |

| 9311近等基因系9311N | CT | 75.57±0.56 a | 12.15±0.37 a | 63.42±0.51 b | 0.19±0.01 a | 70.75±1.71 a |

| QD | 72.15±0.86 b | 7.60±0.26 b | 64.55±1.10 a | 0.12±0 b | 60.75±1.71 b | |

| HD | 71.73±0.37 b | 11.88±0.67 a | 59.85±0.73 c | 0.20±0.01 a | 60.00±2.16 b |

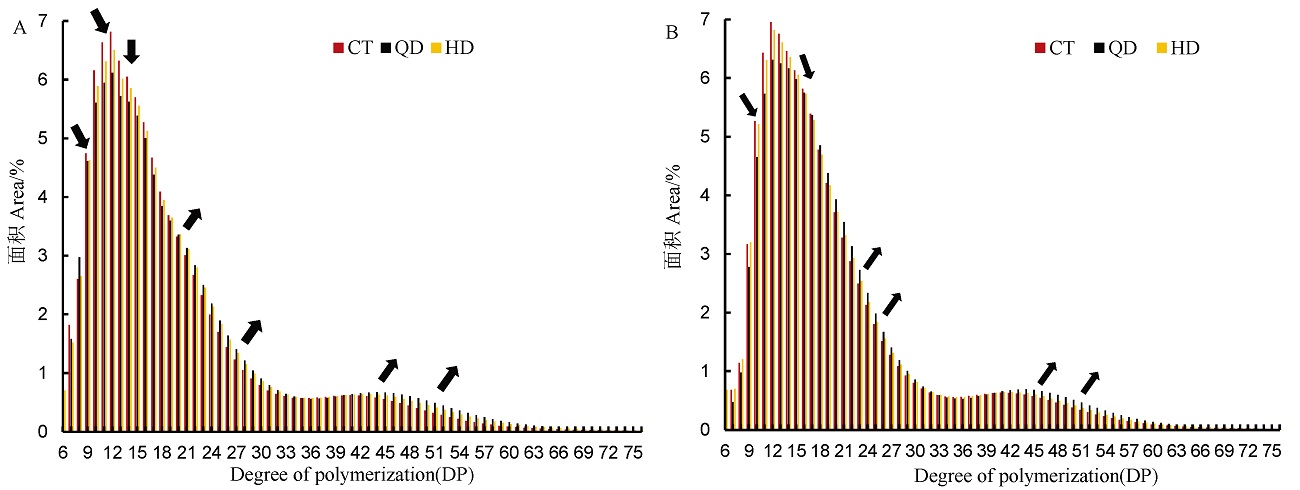

图1 灌浆期不同时段高温对黄华占(A)和9311近等基因系(B)支链淀粉链长分布的影响

Fig. 1. Effect of high temperature at different phases of grain filling on amylopectin chain distribution of heat tolerant variety Huanghuazhan(A) and heat sensitive near-isogenic lines derived from 9311 (B).

| 品种 Variety | 处理时段 Treatment period | 聚合度Degree of polymerization | |||

|---|---|---|---|---|---|

| A(6≤DP≤12) | B1(12<DP≤24) | B2(24<DP≤36) | B3(36<DP≤76) | ||

| 黄华占 Huanghuazhan | CT | 29.90±0.75 a | 49.13±0.60 a | 10.81±0.06 c | 10.17±0.12 c |

| QD | 27.45±0.27 b | 47.59±0.02 c | 11.99±0.17 a | 12.97±0.09 a | |

| HD | 28.21±0.75 b | 48.52±0.20 b | 11.59±0.34 b | 11.68±0.57 b | |

| 9311近等基因系 9311N | CT | 24.41±0.12 a | 54.04±0.01 a | 11.05±0.06 b | 10.49±0.06 b |

| QD | 21.37±0.34 b | 54.42±0.20 a | 11.72±0.11 a | 12.50±0.43 a | |

| HD | 24.13±0.36 a | 53.58±0.12 b | 11.25±0.10 b | 11.04±0.13 b | |

表3 灌浆期不同时段高温对支链淀粉A、B1、B2、B3链含量的影响

Table 3. Effects of high temperature at different phases of grain filling on A, B1, B2, B3 chain of amylopectin. %

| 品种 Variety | 处理时段 Treatment period | 聚合度Degree of polymerization | |||

|---|---|---|---|---|---|

| A(6≤DP≤12) | B1(12<DP≤24) | B2(24<DP≤36) | B3(36<DP≤76) | ||

| 黄华占 Huanghuazhan | CT | 29.90±0.75 a | 49.13±0.60 a | 10.81±0.06 c | 10.17±0.12 c |

| QD | 27.45±0.27 b | 47.59±0.02 c | 11.99±0.17 a | 12.97±0.09 a | |

| HD | 28.21±0.75 b | 48.52±0.20 b | 11.59±0.34 b | 11.68±0.57 b | |

| 9311近等基因系 9311N | CT | 24.41±0.12 a | 54.04±0.01 a | 11.05±0.06 b | 10.49±0.06 b |

| QD | 21.37±0.34 b | 54.42±0.20 a | 11.72±0.11 a | 12.50±0.43 a | |

| HD | 24.13±0.36 a | 53.58±0.12 b | 11.25±0.10 b | 11.04±0.13 b | |

| 品种 Variety | 处理时间 Treatment period | 起始糊化温度 To/℃ | 峰值糊化温度 Tp/℃ | 终止糊化温度 Tc/℃ | 糊化焓 ΔH/(J·g−1) |

|---|---|---|---|---|---|

| 黄华占 Huanghuazhan | CT | 61.91±0.36 c | 67.24±0.56 c | 72.97±0.43 b | 4.34±0.12 b |

| QD | 73.53±0.05 a | 80.54±0.36 a | 84.94±0.48 a | 5.53±0.23 a | |

| HD | 64.21±0.10 b | 68.85±0.18 b | 74.09±0.11 b | 4.24±0.66 b | |

| 9311近等基因系9311N | CT | 71.64±0.17 c | 76.13±0.30 c | 81.64±0.30 b | 6.75±0.04 b |

| QD | 82.08±0.34 a | 87.87±0.39 a | 91.56±0.46 a | 8.40±0.26 a | |

| HD | 73.66±0.15 b | 77.67±0.06 b | 81.87±0.21 b | 5.61±0.31 b |

表4 灌浆期不同时段高温对糊化特性的影响

Table 4. Effect of high temperature at different times of grain filling on gelatinization property.

| 品种 Variety | 处理时间 Treatment period | 起始糊化温度 To/℃ | 峰值糊化温度 Tp/℃ | 终止糊化温度 Tc/℃ | 糊化焓 ΔH/(J·g−1) |

|---|---|---|---|---|---|

| 黄华占 Huanghuazhan | CT | 61.91±0.36 c | 67.24±0.56 c | 72.97±0.43 b | 4.34±0.12 b |

| QD | 73.53±0.05 a | 80.54±0.36 a | 84.94±0.48 a | 5.53±0.23 a | |

| HD | 64.21±0.10 b | 68.85±0.18 b | 74.09±0.11 b | 4.24±0.66 b | |

| 9311近等基因系9311N | CT | 71.64±0.17 c | 76.13±0.30 c | 81.64±0.30 b | 6.75±0.04 b |

| QD | 82.08±0.34 a | 87.87±0.39 a | 91.56±0.46 a | 8.40±0.26 a | |

| HD | 73.66±0.15 b | 77.67±0.06 b | 81.87±0.21 b | 5.61±0.31 b |

| 品种 Variety | 处理时段 Treatment period | 峰值黏度 Peak viscosity | 谷值黏度 Trough viscosity | 崩解值 Breakdown | 最终黏度 Cool paste viscosity | 消减值 Setback |

|---|---|---|---|---|---|---|

| 黄华占 Huanghuazhan | CT | 1893±85 c | 1198±11 c | 695±74 b | 2497±14 b | 604±98 b |

| QD | 2427±88 a | 1735±40 a | 692±48 b | 3357±47 a | 930±41 a | |

| HD | 2028±121 b | 1245±75 b | 782±21 a | 2424±141 b | 396±148 c | |

| 9311近等基因系 9311N | CT | 2064±22 b | 1430±13 b | 634±11 b | 2733±19 b | 669±4 b |

| QD | 2071±13 a | 1613±5 a | 458±10 c | 2945±19 a | 874±8 a | |

| HD | 2073±22 a | 1323±11 c | 750±21 a | 2618±16 c | 545±24 c |

表5 灌浆期不同时段高温对黏度特性的影响

Table 5. Effect of high temperature at different times of grain filling on pasting property. cP

| 品种 Variety | 处理时段 Treatment period | 峰值黏度 Peak viscosity | 谷值黏度 Trough viscosity | 崩解值 Breakdown | 最终黏度 Cool paste viscosity | 消减值 Setback |

|---|---|---|---|---|---|---|

| 黄华占 Huanghuazhan | CT | 1893±85 c | 1198±11 c | 695±74 b | 2497±14 b | 604±98 b |

| QD | 2427±88 a | 1735±40 a | 692±48 b | 3357±47 a | 930±41 a | |

| HD | 2028±121 b | 1245±75 b | 782±21 a | 2424±141 b | 396±148 c | |

| 9311近等基因系 9311N | CT | 2064±22 b | 1430±13 b | 634±11 b | 2733±19 b | 669±4 b |

| QD | 2071±13 a | 1613±5 a | 458±10 c | 2945±19 a | 874±8 a | |

| HD | 2073±22 a | 1323±11 c | 750±21 a | 2618±16 c | 545±24 c |

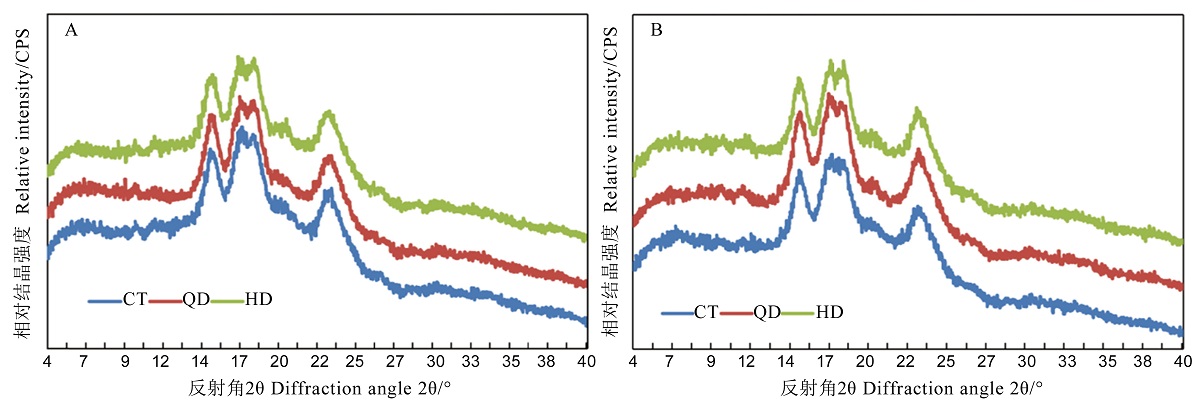

图2 灌浆期不同时段高温对黄华占(A)和9311近等基因系(B)淀粉晶体结构的影响

Fig. 2. Effect of high temperature at different times of grain filling on starch crystal structure of heat tolerant variety Huanghuazhan(A) and heat sensitive near-isogenic lines derived from 9311N (B).

| 品种 Variety | 处理时段 Treatment period | 结晶度 Degree of crystallinity /% | 结晶类型Crystal pattern | 体积占比 Volume percentage/% | 表面积占比 Surface area percentage/% | 数量占比 Number percentage/% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| d<10 μm | d>10 μm | d<10 μm | d>10 μm | d<10 μm | d>10 μm | ||||||

| 黄华占Huanghuazhan | CT | 43.06 | A | 14.49±0.81 b | 85.51±0.81 b | 27.66±1.18 b | 72.34±1.18 a | 61.33±1.35 b | 38.67±1.35 a | ||

| QD | 40.13 | A | 16.93±0.66 a | 83.07±0.66 c | 33.90±0.90 a | 66.10±0.90 b | 71.87±0.75 a | 28.13±0.75 b | |||

| HD | 37.94 | A | 12.57±0.33 c | 87.43±0.33 a | 26.18±0.42 b | 73.82±0.42 a | 63.42±0.52 b | 36.58±0.52 a | |||

| 9311近等基因系9311N | CT | 36.35 | A | 8.21±0.38 c | 91.79±0.38 a | 18.77±0.66 c | 81.23±0.66 a | 51.26±0.93 c | 48.74±0.93 a | ||

| QD | 37.48 | A | 19.96±0.47 a | 80.04±0.47 c | 37.89±0.56 a | 62.11±0.56 c | 73.25±0.44 a | 26.75±0.44 c | |||

| HD | 33.77 | A | 14.69±0.36 b | 85.31±0.36 b | 29.55±0.54 b | 70.45±0.54 b | 65.11±0.55 b | 34.98±0.55 b | |||

表6 灌浆期不同时段高温对淀粉结晶度和粒度分布的影响

Table 6. Effects of high temperature at different times of grain filling on crystallinity and starch granule size distribution.

| 品种 Variety | 处理时段 Treatment period | 结晶度 Degree of crystallinity /% | 结晶类型Crystal pattern | 体积占比 Volume percentage/% | 表面积占比 Surface area percentage/% | 数量占比 Number percentage/% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| d<10 μm | d>10 μm | d<10 μm | d>10 μm | d<10 μm | d>10 μm | ||||||

| 黄华占Huanghuazhan | CT | 43.06 | A | 14.49±0.81 b | 85.51±0.81 b | 27.66±1.18 b | 72.34±1.18 a | 61.33±1.35 b | 38.67±1.35 a | ||

| QD | 40.13 | A | 16.93±0.66 a | 83.07±0.66 c | 33.90±0.90 a | 66.10±0.90 b | 71.87±0.75 a | 28.13±0.75 b | |||

| HD | 37.94 | A | 12.57±0.33 c | 87.43±0.33 a | 26.18±0.42 b | 73.82±0.42 a | 63.42±0.52 b | 36.58±0.52 a | |||

| 9311近等基因系9311N | CT | 36.35 | A | 8.21±0.38 c | 91.79±0.38 a | 18.77±0.66 c | 81.23±0.66 a | 51.26±0.93 c | 48.74±0.93 a | ||

| QD | 37.48 | A | 19.96±0.47 a | 80.04±0.47 c | 37.89±0.56 a | 62.11±0.56 c | 73.25±0.44 a | 26.75±0.44 c | |||

| HD | 33.77 | A | 14.69±0.36 b | 85.31±0.36 b | 29.55±0.54 b | 70.45±0.54 b | 65.11±0.55 b | 34.98±0.55 b | |||

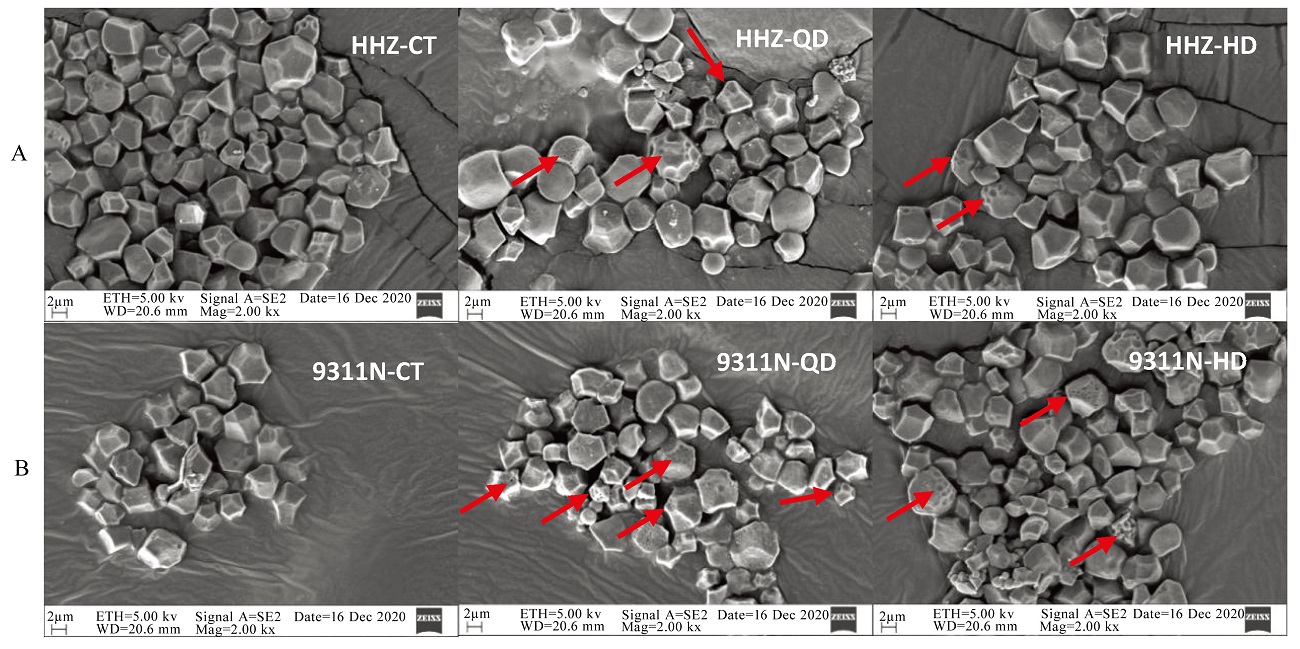

图3 灌浆期不同时段高温对黄华占(A)和9311N(B)近等基因系淀粉颗粒形态结构的影响

Fig. 3. Scanning electron photomicrographs of rice starch from heat tolerant variety Huanghuazhan(A) and heat sensitive near-isogenic lines derived from 9311N (B) as affected by high temperature at various parts of grain-filling.

| [1] | 刘鑫燕, 李娟, 刘雪菊, 张昌泉, 顾铭洪, 刘巧泉. 可溶性淀粉合成酶与稻米淀粉精细结构关系的研究进展[J]. 植物生理学报, 2014, 50(10): 1453-1458. |

| Liu X Y, Li J, Liu X J, Zhang C Q, Gu M H, Liu Q Q. Progress in the relationship between soluble starch synthases and starch fine structure in rice[J]. Plant Physiology Journal, 2014, 50 (10): 1453-1458. (in Chinese with English abstract) | |

| [2] | Thitisaksakul M, Jimenez R C, Arias M C, Beckles D M. Effects of environmental factors on cereal starch biosynthesis and composition[J]. Journal of Cereal Science, 2012, 56(1): 67-80. |

| [3] | Chun A, Lee H J, Hamaker B R, Janaswamy S. Effects of ripening temperature on starch structure and gelatinization, pasting, and cooking properties in rice (Oryza sativa)[J]. Journal of Agricultural and Food Chemistry, 2015, 63(12): 3085-3093. |

| [4] | Zhang C Q, Zhou L H, Zhu Z B, Lu H W, Zhou X Z, Qian Y T, Li Q F, Lu Y, Gu M H, Liu Q Q. Characterization of grain quality and starch fine structure of two japonica rice (Oryza sativa) cultivars with good sensory properties at different temperatures during the filling stage[J]. Journal of Agricultural and Food Chemistry, 2016, 64(20): 4048-4057. |

| [5] | 张桂莲, 张顺堂, 王力, 肖应辉, 唐文帮, 陈光辉, 陈立云. 抽穗结实期不同时段高温对稻米品质的影响[J]. 中国农业科学, 2013, 46(14): 2869-2879. |

| Zhang G L, Zhang S T, Wang L, Xiao Y H, Tang W B, Chen G H, Chen L Y. Effects of high temperature at different times during the heading and filling periods on rice quality[J]. Scientia Agricultura Sinica, 2013, 46(14): 2869-2879. (in Chinese with English abstract) | |

| [6] | Zhang G L, Liao B, Li B, Cai Z H. The effect of high temperature after anthesis on rice quality and starch granule structure of endosperm[J]. Meteorological and Environmental Research, 2016, 7(3): 72-75. |

| [7] | Dou Z, Tang S, Li G H, Ding C Q, Chen L, Wang S H, Ding Y F. Application of nitrogen fertilizer at heading stage improves rice quality under elevated temperature during grain-filling stage[J]. Crop Science, 2017, 57(4): 1-10. |

| [8] | Mitsui T, Shiraya T, Kaneko K, Wada K. Proteomics of rice grain under high temperature stress[J]. Frontiers in Plant Science, 2013, 4: 36. |

| [9] | Ahmed N, Tetlow I J, Nawaz S, Iqbal A, Mubin M, Rehman S, Butt A, Lightfoot D A, Maekawa M. Effect of high temperature on grain filling period, yield, amylose content and activity of starch biosynthesis enzymes in endosperm of basmati rice[J]. Journal of the Science of Food and Agriculture, 2015, 95(11): 2237-2243. |

| [10] | Kong X L, Zhu P, Sui Z Q, Bao J S. Physicochemical properties of starches from diverse rice cultivars varying in apparent amylose content and gelatinisation temperature combinations[J]. Food Chemistry, 2015, 172: 433-440. |

| [11] | Jiang H, Dian W, Wu P. Effect of high temperature on fine structure of amylopectin in rice endosperm by reducing the activity of the starch branching enzyme[J]. Phytochemistry, 2003, 63(1): 53-59. |

| [12] | Gunaratne A, Sirisena N, Ratnayaka U K, Ratnayaka J, Kong X L, Arachchi L P V, Corke H. Effect of fertiliser on functional properties of flour from four rice varieties grown in Sri Lanka[J]. Journal of the Science of Food and Agriculture, 2011, 91(7): 1271-1276. |

| [13] | Lin C J, Li C Y, Lin S K, Yang F H, Huang J J, Liu Y H, Lur H S. Influence of high temperature during grain filling on the accumulation of storage proteins and grain quality in rice (Oryza sativa L.)[J]. Journal of Agricultural and Food Chemistry, 2010, 58(19): 10545-10552. |

| [14] | Umemoto T, Terashima K. Research note: Activity of granule-bound starch synthase is an important determinant of amylose content in rice endosperm[J]. Functional Plant Biology, 2002, 29(9): 1121-1124. |

| [15] | 张桂莲, 廖斌, 李博, 蔡志欢. 花后高温对稻米品质及胚乳淀粉粒结构的影响[J]. 中国农学通报, 2016, 32(9): 10-14. |

| Zhang G L, Liao B, Li B, Cai Z H. Effect of high temperature after anthesis on rice quality and starch granule structure of endosperm[J]. Chinese Agricultural Science Bulletin, 2016, 32(9): 10-14. (in Chinese with English abstract) | |

| [16] | Zhong L J, Cheng F M, Wen X, Sun Z X, Zhang G P. The deterioration of eating and cooking quality caused by high temperature during grain filling in early-season indica rice cultivars[J]. Journal of Agronomy and Crop Science, 2005, 191(3): 218-225. |

| [17] | 徐富贤, 郑家奎, 朱永川, 王贵雄. 灌浆期气象因子对杂交中籼稻米碾米品质和外观品质的影响[J]. 植物生态学报, 2003, 27(1): 73-77. |

| Xu F X, Zheng J K, Zhu Y C, Wang G X. Effect of atmospheric phenomena factors on the milling quality and the appearance quality of medium indica hybrid rice during the period from full heading to maturity[J]. Acta Phytoecologica Sinica, 2003, 27(1): 73-77. (in Chinese with English abstract) | |

| [18] | 程方民, 丁元树, 朱碧岩. 稻米直链淀粉含量的形成及其与灌浆结实期温度的关系[J], 生态学报, 2000, 20(4): 646-652. |

| Cheng F M, Ding Y S, Zhu B Y. The formation of amylose content in rice grain and its relation with field temperature[J]. Acta Ecologica Sinica, 2000, 20(4): 646-652. (in Chinese with English abstract) | |

| [19] | Lanning S B, Siebenmorgen T J, Counce P A, Ambardekar A A. Extreme nighttime air temperatures in 2010 impact rice chalkiness and milling quality[J]. Field Crops Research, 2011, 124(1): 132-136. |

| [20] | Ambardekar A A, Siebenmorgen T J, Counce P A, Lanning S B, Mauromoustakos A. Impact of field-scale nighttime air temperatures during kernel development on rice milling quality[J]. Field Crops Research, 2011, 122(3): 179-185. |

| [21] | 邓化冰, 邓启云, 陈立云, 杨益善, 庄文, 熊跃东. 野生稻增产QTL导入9311之近等基因系的构建[J]. 杂交水稻, 2005, 20(6): 52-56. |

| Deng H B, Deng Q Y, Chen L Y, Yang Y S, Zhuang W, Xiong Y D. Development of Near-isogenic Lines with Yield-enhancing Genes from O. rufipogon by MAS in 9311[J]. Hybrid Rice, 20(6): 52-56. (in Chinese with English abstract) | |

| [22] | Yao D P, Wu J, Luo Q H, Li J W, Zhuang W, Xiao G, Deng Q Y, Lei D Y, Bai B. Influence of high natural field temperature during grain filling stage on the morphological structure and physicochemical properties of rice (Oryza sativa L.) starch[J]. Food Chemistry, 2020, 310: 125817. 1-125817.7. |

| [23] | Xiong R Y, Xie J X, Chen L M, Yang T T, Tan X M, Zhou Y J, Pan X H, Zeng Y J, Shi Q H, Zhang J, Zeng Y H. Water irrigation management affects starch structure and physicochemical properties of indica rice with different grain quality[J]. Food Chemistry, 2021, 347(3): 129045. |

| [24] | 李健陵, 张晓艳, 吴艳飞, 吴丽姬, 杜尧东, 胡飞. 灌浆结实期高温对早稻产量和品质的影响[J]. 中国稻米, 2013, 19(4):50-55. |

| Li J L, Zhang X Y, Wu Y F, Wu L J, Du Y D, Hu F. Effects of high temperature during grain filling stage on yield and quality of early rice[J]. China Rice, 2013, 19(4): 50-55. (in Chinese with English abstract) | |

| [25] | 盛婧, 陶红娟, 陈留根. 灌浆结实期不同时段温度对水稻结实与稻米品质的影响[J]. 中国水稻科学, 2007, 21(4): 396-402. |

| Sheng J, Tao H J, Chen L G. Response of seed setting and grain quality of rice to temperature at different time during grain filling period[J]. Chinese Journal of Rice Science, 2007, 21(4): 396-402. (in Chinese with English abstract) | |

| [26] | 沈鹏, 金正勋, 罗秋香, 金学泳, 孙艳丽. 水稻灌浆过程中籽粒淀粉合成关键酶活性与蒸煮食味品质的关系[J]. 中国水稻科学, 2006, 20(1): 58-64. |

| Shen P, Jin Z X, Luo Q X, Jin X Y, Sun Y L. Relationship between activity of key starch synthetic enzymes during grain filling and quality of eating and cooking in rice[J]. Chinese Journal of Rice Science, 2006, 20(1):58-64. (in Chinese with English abstract) | |

| [27] | Dou Z, Tang S, Chen W Z, Zhang H X, Li G H, Liu Z H, Ding C Q, Chen L, Wang S H, Zhang H C, Ding Y F. Effects of open-field warming during grain-filling stage on grain quality of two japonica rice cultivars in lower reaches of Yangtze River delta[J]. Journal of Cereal Science, 2018, 81: 118-126. |

| [28] | Rehmani M I A, Wei G B, Hussain N, Ding C Q, Li G H, Liu Z H, Wang S H, Ding Y F. Yield and quality responses of two indica rice hybrids to post-anthesis asymmetric day and night open-field warming in lower reaches of Yangtze River delta[J]. Field Crops Research, 2014, 156: 231-241. |

| [29] | 王军可, 王亚梁, 陈惠哲, 向镜, 张义凯, 朱德峰, 张玉屏. 灌浆初期高温影响水稻籽粒碳氮代谢的机理[J]. 中国农业气象, 2020, 41(12): 774-784. |

| Wang J K, Wang Y L, Chen H Z, Xiang J, Zhang Y K, Zhu D F, Zhang Y P. Mechanism of high temperature affecting carbon and nitrogen metabolism of rice grain at the early stage of grain filling[J]. Chinese Journal of Agrometeorology, 2020, 41(12): 774-784. (in Chinese with English abstract) | |

| [30] | 李天. 温光对水稻籽粒碳水化合物代谢及品质的影响[D]. 雅安: 四川农业大学, 2005. |

| Li T. Effects of temperature and light on carbohydrate metabolism and quality in rice grain[D]. Ya’an: Sichuan Agricultural University, 2005. (in Chinese with English abstract) | |

| [31] | 张彩霞. 高温影响水稻韧皮部同化物转运及代谢的作用机制及调控[D]. 北京: 中国农业科学院, 2018. |

| Zhang C X. The mechanism and regulation underlying the inhibition on the assimilates transport and metabolism in phloem of rice caused by heat stress[D]. Beijing: Chinese Academy of Agricultural Sciences, 2018. (in Chinese with English abstract) | |

| [32] | Bao J S, Ying Y, Zhou X, Xu Y, Wu P, Xu F, Pang Y. Relationships among starch biosynthesizing protein content, fine structure and functionality in rice. Carbohydrate Polymers, 2020, 237: 116118. |

| [33] | 闫素辉, 王振林, 尹燕枰, 李文阳, 梁太波, 李勇, 邬云海, 王平, 耿庆辉, 戴忠民. 灌浆期高温对小麦籽粒淀粉的积累、粒度分布及相关酶活性的影响[J]. 作物学报, 2008, 34(6): 1092-1096. |

| Yan S H, Wang Z L, Yin Y P, Li W Y, Liang T B, Li Y, Wu Y H, Wang P, Geng Q H, Dai Z M. Effect of high temperature during grain filling on starch accumulation, starch granule distribution, and activities of related enzymes in wheat grains[J]. Acta Agronomica Sinica, 2008, 34(6): 1092-1096. (in Chinese with English abstract) | |

| [34] | 莫文伟, 旷娜, 郑华斌, 王晓敏, 周蔚, 唐启源. 再生稻与晚稻常规米质及RVA谱特征的对比研究[J]. 湖南农业大学学报: 自然科学版, 2020, 46(3): 271-277. |

| Mo W W, Kuang N, Zheng H B, Wang X M, Zhou W, Tang Q Y. Comparative study on quality and RVA profile parameters of ratoon rice and late rice[J]. Journal of Hunan Agricultural University: Natural Sciences, 2020, 46(3): 271-277. (in Chinese with English abstract) | |

| [35] | Bao J S. Towards understanding of the genetic and molecular basis of eating and cooking quality of rice[J]. Cereal Foods World, 2012, 57: 148-156. |

| [36] | Tong C, Chen Y L, Tang F F, Xu F F, Huang Y, Chen H, Bao J S. Genetic diversity of amylose content and RVA pasting parameters in 20 rice accessions grown in Hainan, China[J]. Food Chemistry, 2014, 161(11): 239-245. |

| [37] | Peng Y, Mao B, Zhang C. Correlations between parental lines and indica hybrid rice in terms of eating quality traits[J]. Frontiers in Nutrition, 2021, 8: 663504. |

| [38] | 成臣, 曾勇军, 程慧煌, 谭雪明, 商庆银, 曾研华, 石庆华. 齐穗至乳熟期不同温度对水稻南粳9108籽粒激素含量、淀粉积累及其合成关键酶活性的影响[J]. 中国水稻科学, 2019, 33(1): 57-67. |

| Cheng C, Zeng Y J, Cheng H H, Tan X M, Shang Q Y, Zeng Y H, Shi Q H. Effects of different temperature from full heading to milking on grain filling stage on grain hormones concentrations, activities of enzymes involved in starch synthesis and accumulation in rice Nanjing 9108[J]. Chinese Journal of Rice Science, 2019, 33(1): 57-67. (in Chinese with English abstract) |

| [1] | 郭展, 张运波. 水稻对干旱胁迫的生理生化响应及分子调控研究进展[J]. 中国水稻科学, 2024, 38(4): 335-349. |

| [2] | 韦还和, 马唯一, 左博源, 汪璐璐, 朱旺, 耿孝宇, 张翔, 孟天瑶, 陈英龙, 高平磊, 许轲, 霍中洋, 戴其根. 盐、干旱及其复合胁迫对水稻产量和品质形成影响的研究进展[J]. 中国水稻科学, 2024, 38(4): 350-363. |

| [3] | 许丹洁, 林巧霞, 李正康, 庄小倩, 凌宇, 赖美玲, 陈晓婷, 鲁国东. OsOPR10正调控水稻对稻瘟病和白叶枯病的抗性[J]. 中国水稻科学, 2024, 38(4): 364-374. |

| [4] | 候小琴, 王莹, 余贝, 符卫蒙, 奉保华, 沈煜潮, 谢杭军, 王焕然, 许用强, 武志海, 王建军, 陶龙兴, 符冠富. 黄腐酸钾提高水稻秧苗耐盐性的作用途径分析[J]. 中国水稻科学, 2024, 38(4): 409-421. |

| [5] | 胡继杰, 胡志华, 张均华, 曹小闯, 金千瑜, 章志远, 朱练峰. 根际饱和溶解氧对水稻分蘖期光合及生长特性的影响[J]. 中国水稻科学, 2024, 38(4): 437-446. |

| [6] | 刘福祥, 甄浩洋, 彭焕, 郑刘春, 彭德良, 文艳华. 广东省水稻孢囊线虫病调查与鉴定[J]. 中国水稻科学, 2024, 38(4): 456-461. |

| [7] | 陈浩田, 秦缘, 钟笑涵, 林晨语, 秦竞航, 杨建昌, 张伟杨. 水稻根系和土壤性状与稻田甲烷排放关系的研究进展[J]. 中国水稻科学, 2024, 38(3): 233-245. |

| [8] | 缪军, 冉金晖, 徐梦彬, 卜柳冰, 王平, 梁国华, 周勇. 过量表达异三聚体G蛋白γ亚基基因RGG2提高水稻抗旱性[J]. 中国水稻科学, 2024, 38(3): 246-255. |

| [9] | 尹潇潇, 张芷菡, 颜绣莲, 廖蓉, 杨思葭, 郭岱铭, 樊晶, 赵志学, 王文明. 多个稻曲病菌效应因子的信号肽验证和表达分析[J]. 中国水稻科学, 2024, 38(3): 256-265. |

| [10] | 朱裕敬, 桂金鑫, 龚成云, 罗新阳, 石居斌, 张海清, 贺记外. 全基因组关联分析定位水稻分蘖角度QTL[J]. 中国水稻科学, 2024, 38(3): 266-276. |

| [11] | 赵艺婷, 谢可冉, 高逖, 崔克辉. 水稻分蘖期干旱锻炼对幼穗分化期高温下穗发育和产量形成的影响[J]. 中国水稻科学, 2024, 38(3): 277-289. |

| [12] | 魏倩倩, 汪玉磊, 孔海民, 徐青山, 颜玉莲, 潘林, 迟春欣, 孔亚丽, 田文昊, 朱练峰, 曹小闯, 张均华, 朱春权. 信号分子硫化氢参与硫肥缓解铝对水稻生长抑制作用的机制[J]. 中国水稻科学, 2024, 38(3): 290-302. |

| [13] | 周甜, 吴少华, 康建宏, 吴宏亮, 杨生龙, 王星强, 李昱, 黄玉峰. 不同种植模式对水稻籽粒淀粉含量及淀粉关键酶活性的影响[J]. 中国水稻科学, 2024, 38(3): 303-315. |

| [14] | 关雅琪, 鄂志国, 王磊, 申红芳. 影响中国水稻生产环节外包发展因素的实证研究:基于群体效应视角[J]. 中国水稻科学, 2024, 38(3): 324-334. |

| [15] | 许用强, 姜宁, 奉保华, 肖晶晶, 陶龙兴, 符冠富. 水稻开花期高温热害响应机理及其调控技术研究进展[J]. 中国水稻科学, 2024, 38(2): 111-126. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||