中国水稻科学 ›› 2025, Vol. 39 ›› Issue (4): 465-476.DOI: 10.16819/j.1001-7216.2025.250303

周斌1,#, 黄江军4,#, 薛晓迪1, 顾伟5, 冯涛5, 孙良1,2,*( ), 俞高红1,3

), 俞高红1,3

收稿日期:2025-03-04

修回日期:2025-04-09

出版日期:2025-07-10

发布日期:2025-07-21

通讯作者:

*email: liangsun@zstu.edu.cn作者简介:#共同第一作者

基金资助:

ZHOU Bin1,#, HUANG Jiangjun4,#, XUE Xiaodi1, GU Wei5, FENG Tao5, SUN Liang1,2,*( ), YU Gaohong1,3

), YU Gaohong1,3

Received:2025-03-04

Revised:2025-04-09

Online:2025-07-10

Published:2025-07-21

Contact:

*email:liangsun@zstu.edu.cn

About author:#These authors contributed equally to this paper

摘要:

【目的】为了解决现有空间轨迹宽窄行分插机构在推秧栽插秧苗时存在秧苗侧向倾斜的问题,本文提出了一种由平面轨迹演变而来的空间轨迹分插机构。【方法】首先,结合水稻秧苗种植要求确定栽植臂秧爪尖点运动轨迹上的若干关键位姿点,构建行星轮系分插机构简化机构(平面2R机构)的运动参数求解模型,并以求解的2R机构整周期角位移对分插机构非圆齿轮进行传动比分配;而后,引入一种共轭凸轮驱动栽植臂侧向运动、分体拨叉实现推秧的摆臂式推秧装置,结合秧爪取秧时刻的姿态角确定栽植臂摆动轴与秧爪的平面夹角;并以平面轨迹段直取秧、侧向摆转定植立苗为要求,设计共轭凸轮廓线和结构参数,实现分插机构取秧过程零偏移量,推秧结束竖直立苗的宽窄行机插。最后,对分插机构进行实物样机试验。【结果】样机的实际轨迹及姿态与理论设计基本一致:取秧角β1=0.75°,xoy平面推秧角β2=55.25°,yoz平面内推秧角β3=34.42°,推秧侧向总偏移量ΔS=39.26 mm,轨迹高度h1=318.86 mm,环扣高度h2=179.83 mm,穴口宽度d1=19.97 mm,满足宽窄行种植的农艺要求,验证了直取直栽式宽窄行分插机构设计的正确性。

周斌, 黄江军, 薛晓迪, 顾伟, 冯涛, 孙良, 俞高红. 直取直栽式空间轨迹宽窄行分插机构运动分析与设计[J]. 中国水稻科学, 2025, 39(4): 465-476.

ZHOU Bin, HUANG Jiangjun, XUE Xiaodi, GU Wei, FENG Tao, SUN Liang, YU Gaohong. Analysis and Design of Wide and Narrow Row Transplanting Mechanism with Direct Picking and Direct Planting[J]. Chinese Journal OF Rice Science, 2025, 39(4): 465-476.

| 参数Parameter | 位姿点Pose point | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| xM(mm) | −106.29 | −195.58 | −134.51 | −109.50 | −16.99 |

| yM(mm) | 68.78 | −25.29 | −242.35 | −246.13 | −36.49 |

| αi(°) | 202.54 | 248.17 | 336.08 | 8.21 | 71.43 |

表1 关键位姿点

Table 1. Key pose point

| 参数Parameter | 位姿点Pose point | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| xM(mm) | −106.29 | −195.58 | −134.51 | −109.50 | −16.99 |

| yM(mm) | 68.78 | −25.29 | −242.35 | −246.13 | −36.49 |

| αi(°) | 202.54 | 248.17 | 336.08 | 8.21 | 71.43 |

| 位姿点 Pose point | xD(mm) | yD(mm) | xM1(mm) | yM1(mm) |

|---|---|---|---|---|

| 1 | −15.105 | −91.545 | −124.993 | 8.652 |

| 2 | 11.001 | −89.434 | −63.049 | −39.487 |

| 3 | −90.048 | −97.691 | −79.682 | −35.611 |

| 4 | −79.419 | −65.010 | −102.333 | −81.723 |

表2 平面2R机构求解结果

Table 2. Solution results of planar 2R mechanism

| 位姿点 Pose point | xD(mm) | yD(mm) | xM1(mm) | yM1(mm) |

|---|---|---|---|---|

| 1 | −15.105 | −91.545 | −124.993 | 8.652 |

| 2 | 11.001 | −89.434 | −63.049 | −39.487 |

| 3 | −90.048 | −97.691 | −79.682 | −35.611 |

| 4 | −79.419 | −65.010 | −102.333 | −81.723 |

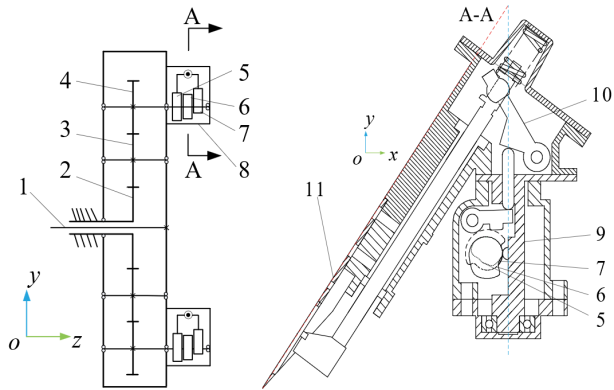

图4 移栽臂结构 1: 中心轴; 2: 太阳轮; 3: 中间轮; 4: 行星轮; 5: 复位凸轮; 6: 推秧凸轮; 7: 摆动凸轮; 8: 移栽臂; 9: 摆动轴; 10: 拨叉; 11: 秧针。

Fig. 4. Schematic diagram of transplanting arm mechanism 1, Central shaft; 2, Sun gear; 3, Intermediate gear; 4, Planetary gear; 5, Return cam; 6, Seedling-pushing cam; 7, Oscillating cam; 8, Transplanting arm; 9, Oscillating shaft; 10, Shifting fork; 11, Seedling needle.

| 参数Parameter | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Ɛi(°) | 0 | 30 | 60 | 90 | 120 | 150 |

| Ci(mm) | 8 | 8 | 8 | 8 | 8.5 | 9 |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Ɛi(°) | 180 | 210 | 240 | 270 | 300 | 330 |

| Ci(mm) | 9.5 | 10 | 10.5 | 11 | 11.5 | 12 |

表3 摆动凸轮型值点位置及向径

Table 3. Position and radial direction of swing cam type value point

| 参数Parameter | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Ɛi(°) | 0 | 30 | 60 | 90 | 120 | 150 |

| Ci(mm) | 8 | 8 | 8 | 8 | 8.5 | 9 |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Ɛi(°) | 180 | 210 | 240 | 270 | 300 | 330 |

| Ci(mm) | 9.5 | 10 | 10.5 | 11 | 11.5 | 12 |

| 参数Parameter | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Ɛi(°) | 0 | 30 | 60 | 90 | 120 | 150 |

| Ri(mm) | 8 | 8 | 8 | 8 | 7.99 | 7.94 |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Ɛi(°) | 180 | 210 | 240 | 270 | 300 | 330 |

| Ri(mm) | 6.50 | 3.96 | 4.01 | 4.43 | 5.82 | 6.48 |

表4 复位凸轮对应型值点位置的向径

Table 4. Radial direction of corresponding type value point position of reset cam

| 参数Parameter | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Ɛi(°) | 0 | 30 | 60 | 90 | 120 | 150 |

| Ri(mm) | 8 | 8 | 8 | 8 | 7.99 | 7.94 |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Ɛi(°) | 180 | 210 | 240 | 270 | 300 | 330 |

| Ri(mm) | 6.50 | 3.96 | 4.01 | 4.43 | 5.82 | 6.48 |

| 参数 Parameter | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Ɛi(°) | 0 | 30 | 60 | 90 | 120 | 150 |

| Ci(mm) | 8 | 8 | 8 | 8 | 8.5 | 9 |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Ɛi(°) | 180 | 210 | 240 | 270 | 300 | 330 |

| Ci(mm) | 9.5 | 10 | 10.5 | 11 | 11.5 | 12 |

表5 优化后的摆动凸轮向径

Table 5. Optimized swing cam radial direction

| 参数 Parameter | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Ɛi(°) | 0 | 30 | 60 | 90 | 120 | 150 |

| Ci(mm) | 8 | 8 | 8 | 8 | 8.5 | 9 |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Ɛi(°) | 180 | 210 | 240 | 270 | 300 | 330 |

| Ci(mm) | 9.5 | 10 | 10.5 | 11 | 11.5 | 12 |

| 参数 Parameter | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Ɛi(°) | 0 | 30 | 60 | 90 | 120 | 150 |

| Ri(mm) | 8 | 8 | 8 | 8 | 7.99 | 7.94 |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Ɛi(°) | 180 | 210 | 240 | 270 | 300 | 330 |

| Ri(mm) | 6.50 | 3.96 | 4.01 | 4.43 | 5.82 | 6.48 |

表6 优化后的复位凸轮向径

Table 6. Optimized reset cam diameter

| 参数 Parameter | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Ɛi(°) | 0 | 30 | 60 | 90 | 120 | 150 |

| Ri(mm) | 8 | 8 | 8 | 8 | 7.99 | 7.94 |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Ɛi(°) | 180 | 210 | 240 | 270 | 300 | 330 |

| Ri(mm) | 6.50 | 3.96 | 4.01 | 4.43 | 5.82 | 6.48 |

| 参数 Parameter | 设计要求 Design requirement | 优化结果Optimization result |

|---|---|---|

| 取秧段侧向偏移量ΔS1 | 0 mm | 0 mm |

| 取秧角β1 | 0°﹤β1﹤20° | 0.15° |

| xoy平面推秧角β2 | 50°﹤β2﹤80° | 55.09° |

| yoz平面推秧角β3 | β3﹤40° | 34.52° |

| 侧向总偏移量ΔS | ≈40 mm | 40.39 mm |

| 静轨迹高度h1 | h1﹥270 mm | 326.80 mm |

| 环扣高度h2 | h2﹥120 mm | 186.80 mm |

| 穴口宽度d1 | d1﹤30 mm | 21.70 mm |

表7 分插机构优化结果与设计要求对比

Table 7. Comparison between optimization results of distributor and design requirements

| 参数 Parameter | 设计要求 Design requirement | 优化结果Optimization result |

|---|---|---|

| 取秧段侧向偏移量ΔS1 | 0 mm | 0 mm |

| 取秧角β1 | 0°﹤β1﹤20° | 0.15° |

| xoy平面推秧角β2 | 50°﹤β2﹤80° | 55.09° |

| yoz平面推秧角β3 | β3﹤40° | 34.52° |

| 侧向总偏移量ΔS | ≈40 mm | 40.39 mm |

| 静轨迹高度h1 | h1﹥270 mm | 326.80 mm |

| 环扣高度h2 | h2﹥120 mm | 186.80 mm |

| 穴口宽度d1 | d1﹤30 mm | 21.70 mm |

| 参数 Parameter | 设计要求 Design requirement | 仿真轨迹 Simulation path |

|---|---|---|

| 取秧段侧向偏移量ΔS1 | 0 mm | 0 mm |

| 取秧角β1 | 0°﹤β1﹤20° | 0.49° |

| xoy平面推秧角β2 | 50°﹤β2﹤80° | 56.77° |

| yoz平面推秧角β3 | β3﹤40° | 35.29° |

| 侧向总偏移量ΔS | ≈40 mm | 40.92 mm |

| 静轨迹高度h1 | h1﹥270 mm | 317.71 mm |

| 环扣高度h2 | h2﹥120 mm | 178.37 mm |

| 穴口宽度d1 | d1﹤30 mm | 20.49 mm |

表8 仿真轨迹参数

Table 8. Simulation path parameters

| 参数 Parameter | 设计要求 Design requirement | 仿真轨迹 Simulation path |

|---|---|---|

| 取秧段侧向偏移量ΔS1 | 0 mm | 0 mm |

| 取秧角β1 | 0°﹤β1﹤20° | 0.49° |

| xoy平面推秧角β2 | 50°﹤β2﹤80° | 56.77° |

| yoz平面推秧角β3 | β3﹤40° | 35.29° |

| 侧向总偏移量ΔS | ≈40 mm | 40.92 mm |

| 静轨迹高度h1 | h1﹥270 mm | 317.71 mm |

| 环扣高度h2 | h2﹥120 mm | 178.37 mm |

| 穴口宽度d1 | d1﹤30 mm | 20.49 mm |

| 参数 Parameter | 设计要求 Design requirement | 实际轨迹 Actual path |

|---|---|---|

| 取秧段侧向偏移量ΔS1 | 0 mm | 0 mm |

| 取秧角β1 | 0°﹤β1﹤20° | 0.75° |

| xoy平面推秧角β2 | 50°﹤β2﹤80° | 55.25° |

| yoz平面推秧角β3 | β3﹤40° | 34.42° |

| 侧向总偏移量ΔS | ≈40 mm | 39.26 mm |

| 静轨迹高度h1 | h1﹥270 mm | 318.86 mm |

| 环扣高度h2 | h2﹥120 mm | 179.83 mm |

| 穴口宽度d1 | d1﹤30 mm | 19.97 mm |

表9 实际轨迹参数

Table 9. Actual path parameter

| 参数 Parameter | 设计要求 Design requirement | 实际轨迹 Actual path |

|---|---|---|

| 取秧段侧向偏移量ΔS1 | 0 mm | 0 mm |

| 取秧角β1 | 0°﹤β1﹤20° | 0.75° |

| xoy平面推秧角β2 | 50°﹤β2﹤80° | 55.25° |

| yoz平面推秧角β3 | β3﹤40° | 34.42° |

| 侧向总偏移量ΔS | ≈40 mm | 39.26 mm |

| 静轨迹高度h1 | h1﹥270 mm | 318.86 mm |

| 环扣高度h2 | h2﹥120 mm | 179.83 mm |

| 穴口宽度d1 | d1﹤30 mm | 19.97 mm |

| [1] | 朱德泉, 储婷婷, 武立权, 张顺, 何海兵. 宽窄行配置对机插中晚稻生长特性及产量的影响[J]. 农业工程学报, 2018, 34(18): 102-112. |

| Zhu D Q, Chu T T, Wu L Q, Zhang S, He H B. The effect of wide narrow row configuration on the growth characteristics and yield of machine inserted late rice[J]. Journal of Agricultural Engineering, 2018, 34(18): 102-112. (in Chinese with English abstract) | |

| [2] | Chen G, Liu M, Xu Y, Zhao G, Bawa B, Liang L, Feng T, Pu T W, Yong W G, Liu J, Liu J B, Du F, Yang Y S, Wu C Y, Liu X C, Wang W Y. Improved photosynthetic performance under unilateral weak light conditions in a wide-narrow-row intercropping system is associated with altered sugar transport[J]. Journal of Experimental Botany, 2024, 75(1): 258-273. |

| [3] | Hu Q, Jiang W Q, Qiu S, Xing Z P, Hu Y J, Guo B W, Liu G D, Gao H, Zhang H C, Wei H Y. Effect of wide-narrow row arrangement in mechanical pot-seedling transplanting and plant density on yield formation and grain quality of italic japonica/italic rice[J]. Journal of Integrative Agriculture, 2020, 19(5): 1197-1214. |

| [4] | 周巍, 王万洪, 郑普兵, 覃艳丽, 王莹莹. 宽窄行栽培技术在再生稻上的应用研究[J]. 中国稻米, 2019, 25(2): 72-74. |

| Zhou W, Wang W H, Zheng P B, Qin Y L, Wang Y Y. Application of wide-narrow row cultivation techniques on ratooning rice[J]. China Rice, 2019, 25(2): 72-74. (in Chinese with English abstract) | |

| [5] | 袁盼盼, 李洪文, 蒋贵菊, 何进, 卢彩云. 滴灌区宽窄行玉米免耕播种带秸秆清理装置设计与试验[J]. 农业机械学报, 2021, 52(6): 43-52. |

| Yuan P P, Li H W, Jiang G J, He J, Lu C Y. Design and experiment of straw cleaning device for wide narrow row corn no tillage sowing belt in drip irrigation area[J]. Journal of Agricultural Machinery, 2021, 52(6): 43-52. (in Chinese with English abstract) | |

| [6] | 赵春江, 马晨, 李瑾, 王小萌. 丘陵山地水稻机械化技术研究现状与展望[J/OL]. 农业工程学报, 2025, 41(1): 1-11. |

| Zhao C J, Ma C, Li J, Wang X M. Research status and prospects of mechanization technology for rice in hilly and mountainous areas[J]. Transactions of the Chinese Society of Agricultural Engineering, 2025, 41(1): 1-11. (in Chinese with English abstract) | |

| [7] | 卢康, 张国忠, 彭少兵, 雷志强, 付建伟, 查显涛, 周勇. 双割台双滚筒全履带式再生稻收割机的设计与性能试验[J]. 华中农业大学学报, 2017, 36(5): 108-114. |

| Lu K, Zhang G Z, Peng S B, Lei Z Q, Fu J W, Zha X T, Zhou Y. Design and performance of tracked harvester for ratoon rice with double-headers and double-threshing cylinders[J]. Journal of Huazhong Agricultural University, 2017, 36(5): 108-114. (in Chinese with English abstract) | |

| [8] | 何永强, 周俊, 袁立存, 郑彭元, 梁子安. 基于履带式联合收获机转向特性的局部跟踪路径规划[J]. 农业机械学报, 2022, 53(11): 13-21. |

| He Y Q, Zhou J, Yuan L C, Zheng P Y, Liang Z A. Local tracking path planning based on the steering characteristics of tracked combine harvesters[J]. Journal of Agricultural Machinery, 2022, 53(11): 13-21. (in Chinese with English abstract) | |

| [9] | Alizadeh M R, Habibi F. A comparative study on the quality of the main and ratoon rice crops[J]. Journal of Food Quality, 2016, 39(6): 669-674. |

| [10] | 吴亦鹏, 杨永涛, 吴昌浩, 贲如城, 张瓷忠, 李革. 一种宽隔板苗箱宽窄行手扶插秧机: ZL201020135597. 9[P]. 2010-03-20. |

| Wu Y P, Yang Y T, Wu C H, Ben R C, Zhang C Z, Li G. A wide partition seedling box wide narrow row hand-held rice transplanter: ZL201020135597. 9[P]. 2010-03-20. (in Chinese) | |

| [11] | 陈林涛, 马旭, 齐龙, 鹿芳媛, 孙国栋. 水稻秧盘育秧流水线自动叠盘装备现状与展望[J]. 农机化研究, 2017, 39(6): 260-264. |

| Chen L T, Ma X, Qi L, Lu F Y, Sun G D. The current situation and prospects of automatic stacking equipment for rice seedling tray production line[J]. Agricultural Mechanization Research, 2017, 39(6): 260-264. (in Chinese with English abstract) | |

| [12] | 张允慧, 迟立军, 赵匀, 徐洪广, 朱艺媛. 斜齿外啮倾斜式宽窄行插秧机分插机构的设计[J]. 农业工程学报, 2012, 28(7): 8-13. |

| Zhang Y H, Chi L J, Zhao Y, Xu H G, Zhu Y Y. Design of the splitting mechanism of the diagonal tooth external mesh tilted wide narrow row transplanter[J]. Journal of Agricultural Engineering, 2012, 28(7): 8-13. (in Chinese with English abstract) | |

| [13] | 王磊, 孙良, 徐亚丹, 俞高红, 张委. 基于空间轨迹的行星轮系移栽机构设计方法研究[J]. 农业机械学报, 2021, 52(7): 51-59. |

| Wang L, Sun L, Xu Y D, Yu G H, Zhang W. Research on the design method of planetary wheel system transplanting mechanism based on spatial trajectory[J]. Journal of Agricultural Machinery, 2021, 52(7): 51-59. (in Chinese with English abstract) | |

| [14] | 许春林, 单伊尹, 辛亮, 解江涛, 李峥. 探出开孔式高速水稻膜上插秧机分插机构设计与试验[J]. 农业机械学报, 2020, 51(5): 79-87. |

| Xu C L, Dan Y Y, Xin L, Jie J T, Li Z. Design and experiment of the splitting mechanism of the high speed rice transplanter with open hole on the film[J]. Journal of Agricultural Machinery, 2020, 51(5): 79-87. (in Chinese with English abstract) | |

| [15] | 徐亚丹, 诸杨华, 薛向磊, 王磊, 孙良. 再生稻空间直取大偏移轮系宽窄行分插机构设计与试验[J]. 农业机械学报, 2022, 53(9): 83-90. |

| Xu Y D, Zhu Y H, Xue X L, Wang L, Sun L. Optimal design and experiment on gear train wide and narrow row transplanting mechanism of spatial direct extraction and large offset of ratooning rice[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(9): 83-90. (in Chinese with English abstract) | |

| [16] | 孙良, 姜凯雯, 周斌, 俞高红, 崔荣江. 取秧侧向零偏移的空间轨迹再生稻分插机构设计与试验[J]. 农业机械学报, 2024, 55(2): 101-108. |

| Sun L, Jiang K W, Zhou B, Yu G H, Cui R J. Design and experiment of regenerated rice on space trajectory transplantation mechanism with zero lateral offset[J]. Transactions of the Chinese Society for Agricultural Machinery, 2024, 55(2): 101-108. (in Chinese with English abstract) | |

| [17] | 俞高红, 王系林, 刘建刚, 叶秉良, 李祥. 蔬菜钵苗密植移栽机多行取苗机构设计与试验[J]. 农业机械学报, 2023, 54(1): 94-103. |

| Yu G H, Wang X L, Liu J G, Ye B L, Li X. Design and experiment of multi row seedling taking mechanism for dense planting and transplanting of vegetable pot peedlings[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(1): 94-103. (in Chinese with English abstract) | |

| [18] | 王磊, 吴启帅, 俞高红, 鲍李旭, 赵雄. 小株距非圆齿轮行星轮系植苗机构设计与试验[J]. 农业机械学报, 2024, 55(11): 294-305. |

| Wang L, Wu Q S, Yu G H, Bao L X, Zhao X. Design and experiment of planting mechanism with small spacing non-circular gear planetary gear system[J]. Journal of Agricultural Machinery, 2024, 55(11): 294-305. (in Chinese with English abstract) | |

| [19] | 童俊华, 俞高红, 朱赢鹏, 叶秉良, 郑超. 三臂回转式蔬菜钵苗取苗机构设计与试验[J]. 农业机械学报, 2019, 50(1): 113-121. |

| Tong J H, Yu G H, Zhu Y P, Ye B L, Zheng C. Design and Experiment of three arm rotary vegetable bowl seedling picking mechanism[J]. Journal of Agricultural Machinery, 2019, 50(1): 113-121. (in Chinese with English abstract) | |

| [20] | 叶秉良, 吴国环, 俞高红, 金学军, 孙良. 非圆齿轮行星轮系水稻钵苗移栽机构优化设计与试验[J]. 农业机械学报, 2016, 47(11): 68-73. |

| Ye B L, Wu G H, Yu G H, Jin X J, Sun L. Optimization design and experiment of rice bowl seedling transplanting mechanism with non circular gear planetary wheel system[J]. Journal of Agricultural Machinery, 2016, 47(11): 68-73. (in Chinese with English abstract) | |

| [21] | 赵雄, 王川, 杨茂祥, 孙良, 陈建能. 非圆齿轮行星轮系自动取苗机构逆向设计分析[J]. 农业工程学报, 2015, 31(16): 30-36. |

| Zhao X, Wang C, Yang M X, Sun L, Chen J N. Reverse design analysis of automatic seedling picking mechanism with non-circular gear planetary gear system[J]. Journal of Agricultural Engineering, 2015, 31(16): 30-36. (in Chinese with English abstract) | |

| [22] | Sun L, Zhou Y Z, Huang H M, Wu C Y, Zhang G F. Analysis and design of a spatial planetary noncircular gear train for rice seedling transplanting based on three given positions[J]. Transactions of the ASABE, 2020, 63(1): 165-176. |

| [23] | 孙良, 胡艺翔, 邢子勤, 俞高红, 俞亚新. 基于近似多位姿的轮系式钵苗移栽机构运动综合[J]. 农业机械学报, 2020, 51(12): 103-111. |

| Sun L, Hu Y X, Xing Z Q, Yu G H, Yu Y X. Motion synthesis of wheel-train pot seedling transplanting mechanism based on approximate multi-pose[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(12): 103-111. (in Chinese with English abstract) | |

| [24] | Zhou M, Sun L, Du X, Zhao Y, Xin L. Optimal design and experiment of rice pot seedling transplanting mechanism with planetary Bezier gears[J]. Transactions of the ASABE, 2014, 57(6): 1537-1548. |

| [25] | Suh C H. On the duality in the existence of R-R links for three positions[J]. Journal of Engineering for Industry, 1969, 91(1): 129-134. |

| [26] | 王磊, 方子辰, 王振涛, 孙良, 俞高红. 不等速行星轮系机构混合多位姿综合方法及应用[J]. 中国机械工程, 2024, 35(12): 2211-2220. |

| Wang L, Fang Z C, Wang Z T, Sun L, Yu G H. Integrated method and application of mixed multi pose for non-uniform planetary gear system mechanism[J]. Chinese Journal of Mechanical Engineering, 2024, 35(12): 2211-2220. | |

| [27] | 孙良, 赵匀, 俞高红, 姚佳明. 基于D-H变换矩阵的宽窄行分插机构运动特性分析与设计[J]. 农业工程学报, 2012, 28(5): 13-18. |

| Sun L, Zhao Y, Yu G H, Yao J M. Analysis and design of motion characteristics of wide narrow row insertion and insertion mechanism based on D-H transform matrix[J]. Journal of Agricultural Engineering, 2012, 28(5): 13-18. (in Chinese with English abstract) |

| No related articles found! |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||