中国水稻科学 ›› 2026, Vol. 40 ›› Issue (1): 131-144.DOI: 10.16819/j.1001-7216.2026.250306

• 研究报告 • 上一篇

谢世民1, 周誉株1, 薛晓迪1, 朱广飞4, 孙良1,2,*( ), 陈建能1,3

), 陈建能1,3

收稿日期:2025-03-06

修回日期:2025-07-25

出版日期:2026-01-10

发布日期:2026-01-21

通讯作者:

*email: liangsun@zstu.edu.cn基金资助:

XIE Shimin1, ZHOU Yuzhu1, XUE Xiaodi1, ZHU Guangfei4, SUN Liang1,2,*( ), CHEN Jianneng1,3

), CHEN Jianneng1,3

Received:2025-03-06

Revised:2025-07-25

Online:2026-01-10

Published:2026-01-21

摘要:

【目的】针对现有取苗与栽植一体式移栽机构作业时夹带泥土影响二次取苗及秧苗栽插直立度的问题,本研究提出了一种取苗与栽植双机构协同作业的水稻钵苗移栽方式。【方法】首先,结合钵苗夹取、交接、栽植要求,设定移栽过程的若干关键位姿点作为取与栽植动作的约束条件,规划运动轨迹;依据杆长不变原理构建平面2R机构多位姿近似运动综合模型,采用粒子群优化(PSO)算法求解机构两转动副的最优布局,确定杆长,并建立了交接段的几何约束;结合转动副位置与杆长参数复演运动轨迹,求解两构件相对角位移,获取非圆齿轮传动比。为改善非圆齿轮节曲线凹凸性,建立节曲线圆度系数目标函数,利用PSO算法实现非圆齿轮圆度优化,完成取苗与栽植两轮系机构的设计。【结果】对机构的仿真分析与台架试验表明:机构实际运动轨迹与理论轨迹最大偏差小于1.8 mm,关键位姿夹取角度误差不超过1.2 °,移栽成功率可达88.7%。【结论】本研究采用取栽分离协同作业模式,可有效解决传统机构夹带泥土导致的移栽效果不佳问题,为高效水稻钵苗移栽装备研发提供了新的理论依据。

谢世民, 周誉株, 薛晓迪, 朱广飞, 孙良, 陈建能. 水稻钵苗取栽协同作业式移栽机构设计与试验[J]. 中国水稻科学, 2026, 40(1): 131-144.

XIE Shimin, ZHOU Yuzhu, XUE Xiaodi, ZHU Guangfei, SUN Liang, CHEN Jianneng. Design and Experiment of an Integrated Picking and Planting Mechanism for Rice Pot Seedlings[J]. Chinese Journal OF Rice Science, 2026, 40(1): 131-144.

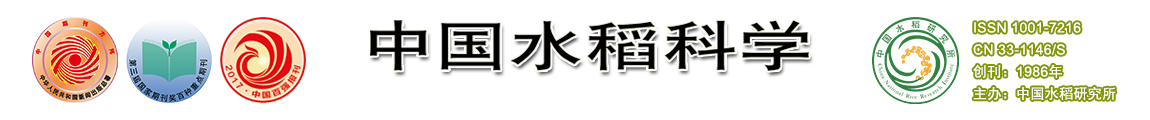

图1 取苗,交接和栽植过程示意图 1 : 取苗机构; 2: 取苗轨迹; 3: 栽植轨迹; 4: 栽植机构; 5: 秧箱。

Fig. 1. Schematic diagram of seedling picking, handover, and planting process 1, Seedling picking mechanism; 2, Seedling picking trajectory; 3, Planting trajectory; 4, Planting mechanism; 5, Seedling tray.

| 取苗位姿点 Picking pose point | 1 | 2 | 3 | 4 | 5 | 6 | 栽植位姿点 Transplanting pose point | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| x(mm) | 369.25 | 335.57 | 172.09 | 253.60 | 341.97 | 373.18 | x(mm) | 185.65 | 28.47 | 0.00 | 49.68 | 30.45 | 26.10 |

| y(mm) | 225.00 | 245.23 | 61.23 | 12.39 | 138.41 | 185.38 | y(mm) | 67.50 | −211.25 | −215.00 | −146.60 | −36.10 | 172.78 |

| θ(°) | −90.00 | −95.58 | −55.00 | −24.66 | −63.43 | −80.42 | θ(°) | 180.00 | 91.01 | 90.00 | 146.57 | 178.01 | −129.69 |

表1 取苗、栽植轨迹位姿点

Table 1. Posture points of seedling picking and planting trajectories

| 取苗位姿点 Picking pose point | 1 | 2 | 3 | 4 | 5 | 6 | 栽植位姿点 Transplanting pose point | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| x(mm) | 369.25 | 335.57 | 172.09 | 253.60 | 341.97 | 373.18 | x(mm) | 185.65 | 28.47 | 0.00 | 49.68 | 30.45 | 26.10 |

| y(mm) | 225.00 | 245.23 | 61.23 | 12.39 | 138.41 | 185.38 | y(mm) | 67.50 | −211.25 | −215.00 | −146.60 | −36.10 | 172.78 |

| θ(°) | −90.00 | −95.58 | −55.00 | −24.66 | −63.43 | −80.42 | θ(°) | 180.00 | 91.01 | 90.00 | 146.57 | 178.01 | −129.69 |

| 第一组Group 1 | 第二组Group 2 | ||

|---|---|---|---|

| (xB1, yB1) | (66.85,67.50) | (xB2, yB2) | (51.24,80.00) |

| (xC1, yC1) | (185.65,67.50) | (xC2, yC2) | (180.17,90.14) |

| (xD1, yD1) | (308.20,21.90) | (xD2, yD2) | (308.20,21.90) |

| (xE1, yE1) | (246.42,-47.28) | (xE2, yE2) | (233.31,-32.82) |

| (xF1, yF1) | (172.09,61.23) | (xF2, yF2) | (171.18,76.25) |

表2 交接段始末位置坐标数据

Table 2. Coordinate data of the beginning and end positions of the handover section

| 第一组Group 1 | 第二组Group 2 | ||

|---|---|---|---|

| (xB1, yB1) | (66.85,67.50) | (xB2, yB2) | (51.24,80.00) |

| (xC1, yC1) | (185.65,67.50) | (xC2, yC2) | (180.17,90.14) |

| (xD1, yD1) | (308.20,21.90) | (xD2, yD2) | (308.20,21.90) |

| (xE1, yE1) | (246.42,-47.28) | (xE2, yE2) | (233.31,-32.82) |

| (xF1, yF1) | (172.09,61.23) | (xF2, yF2) | (171.18,76.25) |

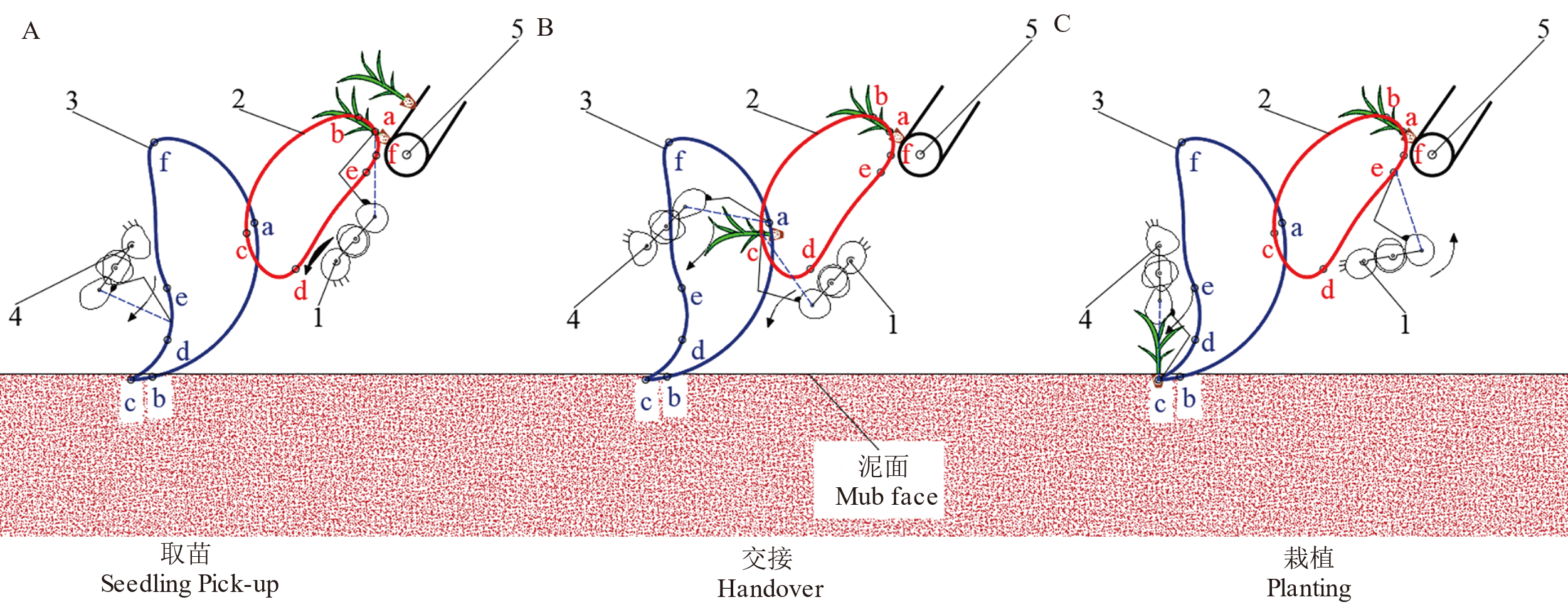

图7 移栽部件结构 1 : 凸轮; 2: 凸轮顶杆; 3: 杆一; 4: 杆二; 5: 固定杆; 6: 夹片A; 7: 夹片B; 8: 弹簧。

Fig. 7. Schematic diagram of transplanting component structure 1, Cam; 2, Cam follower; 3, Rod 1; 4, Rod 2; 5, Fixed rod; 6, Clip A; 7, Clip B; 8, Spring.

| 取苗段 Seedling-picking | y1 | y2 | y3 | y4 | y5 |

|---|---|---|---|---|---|

| 最优值 Optimal value | −2.428 | −2.708 | −3.360 | −4.221 | −4.904 |

| 上限值 Upper limit | −2.202 | −2.202 | −2.202 | −2.202 | −2.202 |

| 下限值 Lower limit | −5.560 | −5.560 | −5.560 | −5.560 | −5.560 |

表3 取苗段角位移最优值

Table 3. Optimal values of angular displacement for seedling-picking

| 取苗段 Seedling-picking | y1 | y2 | y3 | y4 | y5 |

|---|---|---|---|---|---|

| 最优值 Optimal value | −2.428 | −2.708 | −3.360 | −4.221 | −4.904 |

| 上限值 Upper limit | −2.202 | −2.202 | −2.202 | −2.202 | −2.202 |

| 下限值 Lower limit | −5.560 | −5.560 | −5.560 | −5.560 | −5.560 |

| 栽植段 Seedling planting | y1 | y2 | y3 | y4 | y5 |

|---|---|---|---|---|---|

| 最优值 Optimal value | 4.645 | 4.005 | 3.472 | 2.764 | 2.304 |

| 上限值 Upper limit | 5.030 | 5.030 | 5.030 | 5.030 | 5.030 |

| 下限值 Upper limit | 1.547 | 1.547 | 1.547 | 1.547 | 1.547 |

表4 栽植段角位移最优值

Table 4. Optimal value of angular displacement for seedling planting

| 栽植段 Seedling planting | y1 | y2 | y3 | y4 | y5 |

|---|---|---|---|---|---|

| 最优值 Optimal value | 4.645 | 4.005 | 3.472 | 2.764 | 2.304 |

| 上限值 Upper limit | 5.030 | 5.030 | 5.030 | 5.030 | 5.030 |

| 下限值 Upper limit | 1.547 | 1.547 | 1.547 | 1.547 | 1.547 |

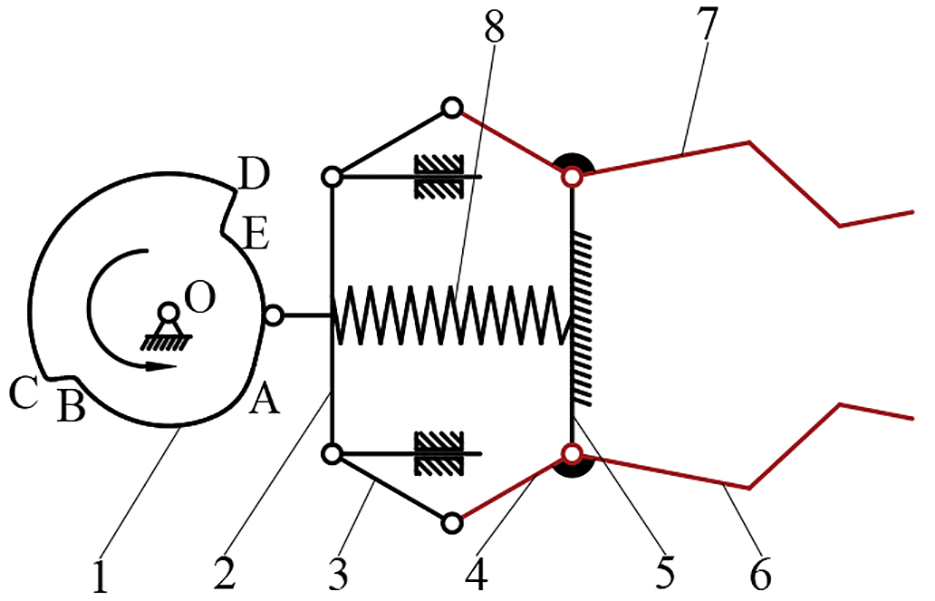

图11 取栽机构角位移-节曲线-轨迹优化前后对比

Fig. 11. Comparison of angular displacement-pitch curve-trajactory before and after optimization of the picking and planting mechanism

| 类型 Type | 取苗角 Seedling-picking angle | 交接角 Intersection angle | 栽植角 Planting angle | ||

|---|---|---|---|---|---|

| 取苗机构 Seedling collection mechanism | 栽植机构 Seedling-planting mechanism | ||||

| 理论设计值Theoretical design value | 59.0° | 94.0° | −40.0° | −130.0° | |

| 虚拟仿真值Virtual simulation value | 58.8° | 94.3° | −40.2° | −129.9° | |

| 样机试验值 Prototype test values | 第1组Group 1 | 59.8° | 94.6° | −38.9° | −128.8° |

| 第2组Group 2 | 58.1° | 93.2° | −39.5° | −130.3° | |

| 第3组Group 3 | 60.2° | 93.7° | −40.2° | −130.9° | |

表5 移栽关键姿态角

Table 5. Key attitude angle of the transplanting mechanism

| 类型 Type | 取苗角 Seedling-picking angle | 交接角 Intersection angle | 栽植角 Planting angle | ||

|---|---|---|---|---|---|

| 取苗机构 Seedling collection mechanism | 栽植机构 Seedling-planting mechanism | ||||

| 理论设计值Theoretical design value | 59.0° | 94.0° | −40.0° | −130.0° | |

| 虚拟仿真值Virtual simulation value | 58.8° | 94.3° | −40.2° | −129.9° | |

| 样机试验值 Prototype test values | 第1组Group 1 | 59.8° | 94.6° | −38.9° | −128.8° |

| 第2组Group 2 | 58.1° | 93.2° | −39.5° | −130.3° | |

| 第3组Group 3 | 60.2° | 93.7° | −40.2° | −130.9° | |

| 类型 Type | 取苗 Picking | 交接 Handover | 栽植 Planting | 移栽成功率 Transplant success rate(%) | |

|---|---|---|---|---|---|

| 样机试验值 Prototype test values | 第1组Group 1 | 49/50 | 45/49 | 44/45 | 88.0 |

| 第2组Group 2 | 47/50 | 44/47 | 44/44 | 88.0 | |

| 第3组Group 3 | 49/50 | 46/49 | 45/46 | 90.0 | |

| 平均值Average(%) | 96.7 | 93.1 | 98.5 | 88.7 | |

表6 移栽成功率

Table 6. Transplant success rate

| 类型 Type | 取苗 Picking | 交接 Handover | 栽植 Planting | 移栽成功率 Transplant success rate(%) | |

|---|---|---|---|---|---|

| 样机试验值 Prototype test values | 第1组Group 1 | 49/50 | 45/49 | 44/45 | 88.0 |

| 第2组Group 2 | 47/50 | 44/47 | 44/44 | 88.0 | |

| 第3组Group 3 | 49/50 | 46/49 | 45/46 | 90.0 | |

| 平均值Average(%) | 96.7 | 93.1 | 98.5 | 88.7 | |

| [1] | 李泽华, 马旭, 李秀昊, 陈林涛, 李宏伟, 袁志成. 水稻栽植机械化技术研究进展[J]. 农业机械学报, 2018, 49(5): 1-20. |

| Li Z H, Ma X, Li X H, Chen L T, Li H W, Yuan Z C. Research progress on mechanization technology of rice planting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49 (5): 1-20. (in Chinese with English abstract) | |

| [2] | 朱均林, 褚光, 章秀福. 近年我国水稻栽培学科若干热点领域研究进展与展望[J]. 中国稻米, 2023, 29(6): 5-9. |

| Zhu J L, Chu G, Zhang X F. Research progress and prospects in several hot areas of rice cultivation in China in recent years[J]. China Rice, 2023, 29 (6): 5-9. (in Chinese with English abstract) | |

| [3] | 李泽华, 马旭, 陈林涛, 李宏伟, 黄益强, 黎俊荣, 罗国武, 姚俊豪. 育秧播种密度与取秧面积耦合对杂交稻机插质量和产量的影响[J]. 农业工程学报, 2019, 35(24): 20-30. |

| Li Z H, Ma X, Chen L T, Li H W, Huang Y Q, Li J R, Luo G W, Yao J H. The Influence of coupling between seedling density and seedling area on the quality and yield of hybrid rice machine insertion[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35 (24): 20-30. (in Chinese with English abstract) | |

| [4] | 俞高红, 金也, 常数数, 叶秉良, 顾锦波, 赵雄. 夹钵式水稻钵苗移栽机构设计与试验[J]. 农业机械学报, 2019, 50(7): 100-108. |

| Yu G H, Jin Y, Chang S S, Ye B L, Gu J B, Zhao X. Design and experiment of rice bowl seedling transplanting mechanism with clamp bowl[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50 (7): 100-108. (in Chinese with English abstract) | |

| [5] | 辛亮, 王明成, 张浩, 孙国玉, 王航, 庄智圆. 非圆齿轮-连杆组合式水稻钵苗膜上移栽机构优化设计与试验[J]. 农业机械学报, 2024, 55(8): 63-70. |

| Xin L, Wang M C, Zhang H, Sun G Y, Wang H, Zhuang Z Y. Optimization design and experiment of non circular gear connecting rod combination rice bowl seedling membrane transplanting mechanism[J]. Transactions of the Chinese Society for Agricultural Machinery, 2024, 55 (8): 63-70. (in Chinese with English abstract) | |

| [6] | 张静, 龙新华, 韩长杰, 袁盼盼, 高杰. 机械驱动式辣椒穴盘苗自动取投苗系统设计与试验[J]. 农业工程学报, 2021, 37(5): 20-30. |

| Zhang J, Long X H, Han C J, Yuan P P, Gao J. Design and experiment of automatic seedling picking and feeding system for mechanically driven chili plug seedlings[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37 (5): 20-30. (in Chinese with English abstract) | |

| [7] | 辛亮, 王明成, 孙国玉, 张浩, 孙铭翼, 王航. 番茄钵苗移栽探出式取钵机构设计与试验[J]. 农业机械学报, 2024, 55(3): 96-105. |

| Xin L, Wang M C, Sun G Y, Zhang H, Sun M Y, Wang H. Design and experiment of tomato bowl seedling transplanting and protruding bowl picking mechanism[J]. Transactions of the Chinese Society for Agricultural Machinery, 2024, 55 (3): 96-105. (in Chinese with English abstract) | |

| [8] | 俞高红, 俞腾飞, 叶秉良, 贾德宝, 王林伟, 胡海军. 一种新型行星轮系机构的研究[J]. 机械工程学报, 2013, 49(15): 55-61. |

| Yu G H, Yu T F, Ye B L, Jia D B, Wang L W, Hu H J. Research on a new type of planetary gear system mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 49 (15): 55-61. (in Chinese with English abstract) | |

| [9] | 赵匀, 朱慧轩, 辛亮, 周脉乐, 冯江, 张敏. 拟合齿轮五杆水稻钵苗移栽机构的机理分析与试验[J]. 农业工程学报, 2016, 32(1): 12-21. |

| Zhao Y, Zhu H X, Xin L, Zhou M L, Feng J, Zhang M. Mechanism analysis and experiment of fitting gear five bar rice bowl seedling transplanting mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32 (1): 12-21. (in Chinese with English abstract) | |

| [10] | 周脉乐, 薛向磊, 钱孟波, 尹大庆. 探出式蔬菜钵苗打孔移栽机构优化设计与试验[J]. 农业机械学报, 2020, 51(1): 77-83. |

| Zhou M L, Xue X L, Qian M B, Yin D Q. Optimization design and experiment of drilling and transplanting mechanism for protruding vegetable bowl seedlings[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51 (1): 77-83. (in Chinese with English abstract) | |

| [11] | 蔡金平, 刘木华, 肖丽萍, 林金龙, 叶洋洋, 杨红飞. 变行距水稻钵苗移栽机移栽装置设计与试验[J]. 农业机械学报, 2020, 51(4): 50-59. |

| Cai J P, Liu M H, Xiao L P, Lin J L, Ye Y Y, Yang H F. Design and experiment of transplanting device for rice bowl seedling transplanter with variable row spacing[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51 (4): 50-59. (in Chinese with English abstract) | |

| [12] | 于晓旭, 赵匀, 陈宝成, 周脉乐, 张昊, 张智超. 移栽机械发展现状与展望[J]. 农业机械学报, 2014, 45(8): 44-53. |

| Yu X X, Zhao Y, Chen B C, Zhou M L, Zhang H, Zhang Z C. Development status and prospects of transplanting machinery[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45 (8): 44-53. (in Chinese with English abstract) | |

| [13] | 陈雄飞, 黄活龙, 廖仲维, 余佳佳, 刘俊安, 肖丽萍, 伍金峰, 刘木华. 水稻钵体苗凸轮渐进顶出式取苗装置设计与试验[J]. 农业工程学报, 2025, 41(1): 65-74. |

| Chen X F, Huang H L, Liao Z W, Yu J J, Liu J A, Xiao L P, Wu J F, Liu M H. Design and experiment of rice bowl seedling cam progressive ejection seedling picking device[J]. Transactions of the Chinese Society of Agricultural Engineering, 2025, 41(1): 65-74. (in Chinese with English abstract) | |

| [14] | 张洪程, 戴其根, 霍中洋, 许轲, 魏海燕. 中国抛秧稻作技术体系及其特征[J]. 中国农业科学, 2008, 41(1): 43-52. |

| Zhang H C, Dai Q G, Huo Z Y, Xu K, Wei H Y. The technical system and characteristics of rice seedling throwing in China[J]. Scientia Agricultura Sinica, 2008, 41(1): 43-52. | |

| [15] | 王磊, 孙良, 徐亚丹, 俞高红, Gervais N L, 黄佳辉. 基于遗传算法的三臂轮系式栽植机构多位姿运动综合[J]. 农业机械学报, 2022, 53(6): 70-77. |

| Wang L, Sun L, Xu Y D, Yu G H, Gervais N L, Huang J H. Multi pose motion synthesis of three arm wheel system planting mechanism based on genetic algorithm[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(6): 70-77. (in Chinese with English abstract) | |

| [16] | 许春林, 吕志军, 辛亮, 王杰, 赵匀. 步行式水稻钵苗膜上开孔移栽机构优化设计与试验[J]. 农业机械学报, 2019, 50(8): 90-96. |

| Xu C L, Lü Z J, Xin L, Wang J, Zhao Y. Optimization design and experiment of a walking rice bowl seedling membrane hole transplanting mechanism[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50 (8): 90-96. (in Chinese with English abstract) | |

| [17] | 孙良, 徐亚丹, 黄恒敏, 王振飞, 张国凤, 武传宇. 基于节曲线凸性判别的行星轮系移栽机构解析[J]. 农业机械学报, 2018, 49(12): 83-92. |

| Sun L, Xu Y D, Huang H M, Wang Z F, Zhang G F, Wu C Y. Analysis of planetary gear transplanting mechanism based on convexity discrimination of nodal curves[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49 (12): 83-92. (in Chinese with English abstract) | |

| [18] | Tong Z, Yu G, Zhao X, Liu P, Ye B. Design of vegetable pot seedling pick-up mechanism with planetary gear train[J]. Chinese Journal of Mechanical Engineering, 2020, 33: 63. |

| [19] | 王磊. 基于多元函数极值理论的机构多位姿运动综合方法及试验研究[D]. 杭州: 浙江理工大学, 2022. |

| Wang L. Method and experimental study on multi pose motion synthesis of mechanisms based on the extreme value theory of multivariate functions[D]. Hangzhou: Zhejiang Sci-Tech University, 2022. (in Chinese with English abstract) | |

| [20] | 朱立红. 基于Kinematic-Mapping的运动综合理论及其在辅助康复机构中的应用[D]. 合肥: 合肥工业大学, 2016. |

| Zhu L H. Motion synthesis theory based on Kinematic Mapping and its application in assisted rehabilitation institutions[D]. Hefei: Hefei University of Technology, 2016. (in Chinese with English abstract) | |

| [21] | Clerc M, Kennedy J. The particle swarm-explosion, stability, and convergence in a multidimensional complex space[J]. IEEE Transactions on Evolutionary Computation, 2002, 6(1): 58-73. |

| [22] | Eberhart R, Kennedy J. A new optimizer using particle swarm theory[C]// MHS'95. Proceedings of the Sixth International Symposium on Micro Machine and Human Science. October 4-6, 1995, Nagoya, Japan. IEEE, 2002: 39-43. |

| [23] | 李学艺, 王钊, 连小珉, 曾庆良. 基于周期性延伸的三次B样条闭曲线插值[J]. 农业机械学报, 2009, 40(12): 251-254. |

| Li X Y, Wang Z, Lian X M, Zeng Q L. Triple B-spline closed curve interpolation based on periodic extension[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40 (12): 251-254. (in Chinese with English abstract) | |

| [24] | 夏成林, 邬弘毅, 郑兴国, 彭凯军. 带多个形状参数的三次均匀B样条曲线的扩展[J]. 工程图学学报, 2011, 32(2): 73-79. |

| Xia C L, Wu H Y, Zheng X G, Peng K J. Extension of cubic uniform B-spline curves with multiple shape parameters[J]. Journal of Engineering Graphics, 2011, 32 (2): 73-79. (in Chinese with English abstract) | |

| [25] | 孙良, 邢子勤, 徐亚丹, 刘兵, 俞高红, 武传宇. 基于精确多位姿解析的水稻钵苗移栽机构研究[J]. 农业机械学报, 2019, 50(9): 78-86. |

| Sun L, Xing Z Q, Xu Y D, Liu B, Yu G H, Wu C Y. Research on rice bowl seedling transplanting mechanism based on precise multi pose analysis[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(9): 78-86. (in Chinese with English abstract) |

| No related articles found! |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||